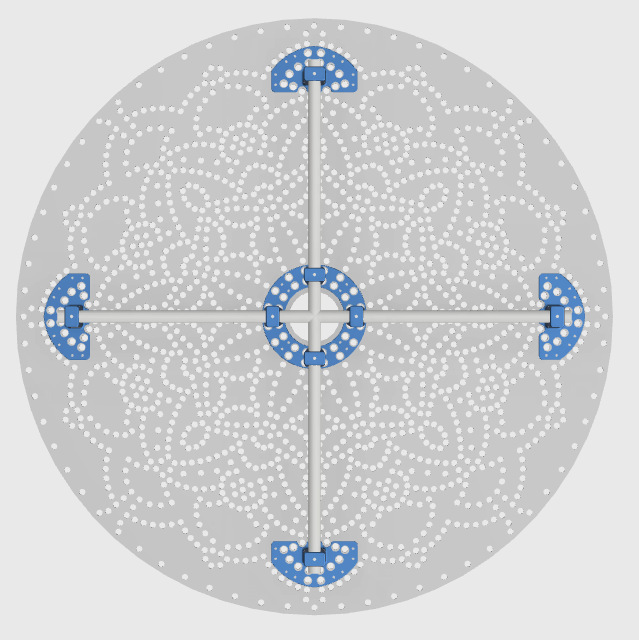

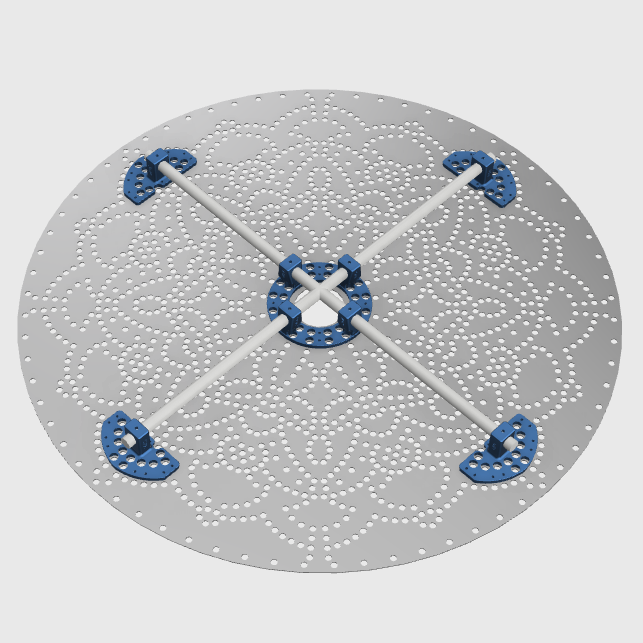

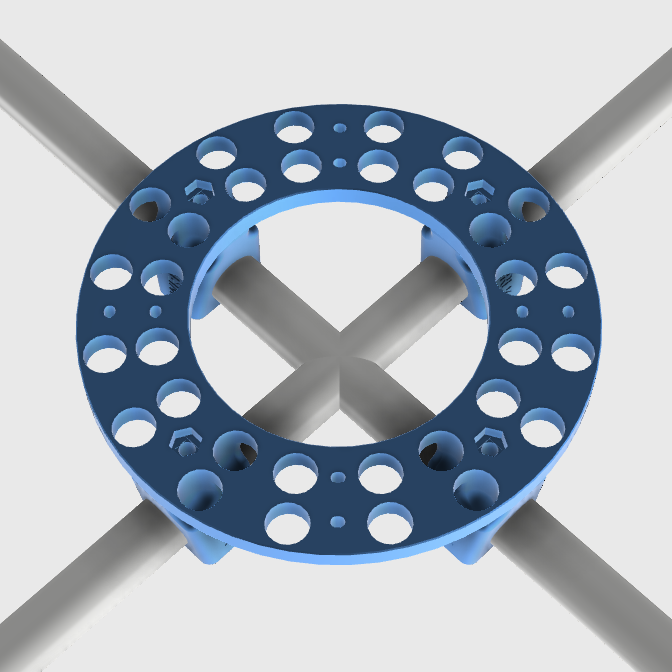

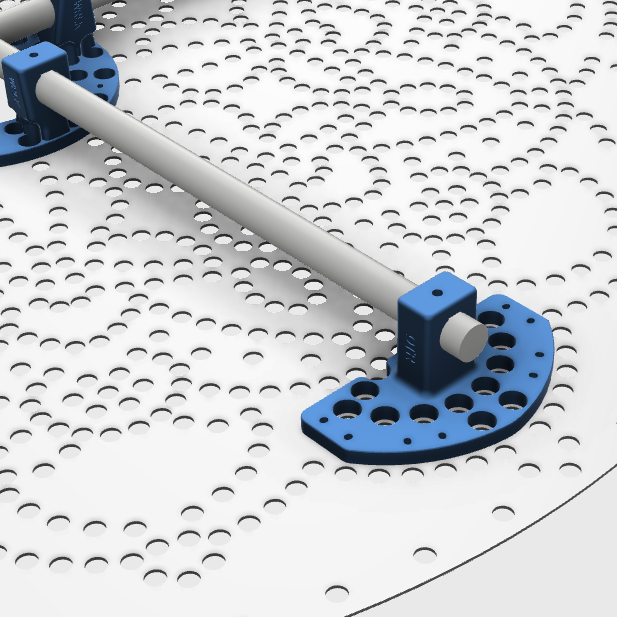

Because of the high weight and pixel density of the Warlock prop, the mounts are designed to be both zip-tied and bolted directly to the coro for maximum strength. Each of the 8 post mounts requires:

- (1x) 3.5″ long 1/4″-20 bolt

- (2x) 1/4″-20 nuts

- (1x) 1/4″ washer

- Zip ties

Step-by-step instructions:

-

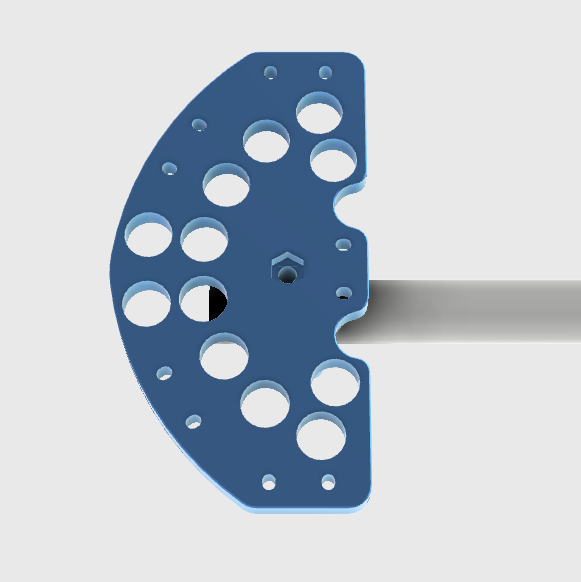

Install embedded nuts: Begin by inserting a 1/4″-20 nut into the bottom of each post mount. You can do this in one of two ways:

– Gently tap the nut into place with a mallet or other non-marring tool.

– Or temporarily thread the nut onto a bolt inserted from the top of the mount and tighten it to pull the nut down into its pocket. -

Mark mounting holes: Use each mount to mark the coro for the bolt hole and zip tie slots. While the prop may appear symmetrical, hole locations vary slightly at the outer mounts. These mounts are based on the average hole spacing, so they won’t align perfectly—just center each mount visually among the nearby holes. There is sufficient clearance.

-

Attach mounts to coro: Drill the marked holes and zip tie each mount to the prop.

-

Prepare conduit: Insert 3/4″ EMT conduit into the mounts and mark the bolt pass-through locations. If the prop was split for shipping, it’s best practice to run the continuous EMT section perpendicular to the split.

-

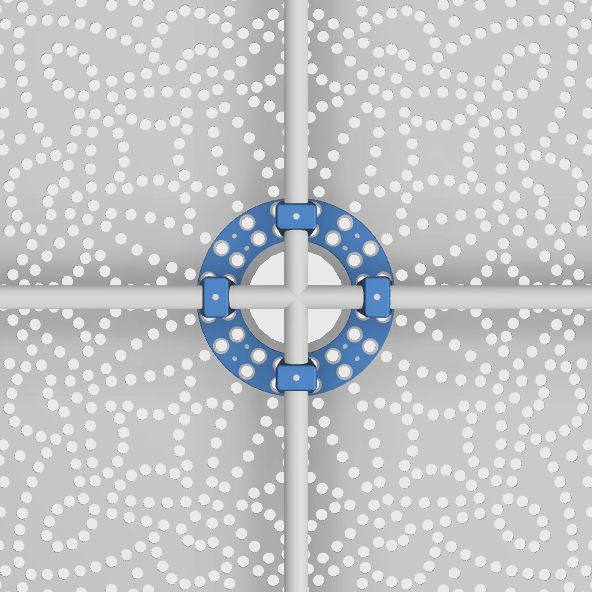

Drill conduit: Drill 1/4″ holes all the way through the EMT at each marked location.

-

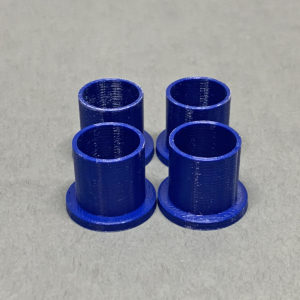

Assemble center junction: Glue the EMT-to-PVC bushings into the 3/4″ PVC cross using epoxy or super glue. Insert the EMT into the mounts with the center cross in place.

-

Secure the frame: Insert each 3.5″ bolt from the top of the mount, tighten it into the embedded nut, and continue the bolt through the coro. Tighten until snug, but avoid over-tightening to prevent cracking the printed mount.

-

Lock from the front: From the front of the prop, secure the exposed bolt with a 1/4″ washer and second 1/4″-20 nut.

As with all our designs, we strive to utilize the precut zip tie hole locations for our mounts. However, these pre-made holes don’t always align perfectly for optimal mount placement, which means you may need to create additional holes in the coro to secure the mounts with zip ties.

3D printing parts is a slow process and we have a whole print farm running 24/7 to fulfill orders and build stock of the more popular items. If you order a product that shows “made to order” we will move it directly to the print queue where it will be printed as soon as possible. While normal processing times for most orders with made to order items is less than a week, it can fluctuate. Very large orders can also experience longer than normal processing times as well because of the high number of hours it takes to produce lots of parts. If processing times are expected to be longer than two weeks before shipping, there will be a banner at the top of the website indicating the expected wait times. See the FAQ page for more info.

All of our 3D printed parts use PETG filament which provides good flexibility and resistance to UV exposure when used seasonally.

Reviews

There are no reviews yet.